Precision Laser Cutting & Punching Fabrication

Since pioneering laser technology back in the 1980s, Jensen Metal Products has been at the forefront of the metal fabrication industry. We proudly offer an extensive selection of advanced equipment allowing us to meet all your laser cutting and punching requirements.

Laser cutting is a fantastic process for cutting many metals. The accuracy, speed and versatility of laser cutters provide many advantages, making complex shapes and designs easy to handle while often reducing scrap and minimizing the need for secondary finishing operations. From the thinnest of metals to ¾” thick plate, our advanced laser cutting technologies enhance efficiency and yield a high-output of precision-cut metal products. Available laser etching lets us address marking requirements, such as branding, part numbering, safety and caution messaging and other quality management system standards quickly and efficiently.

Advanced Metal Laser Cutting Technology

Innovative Laser Solutions

- Our sheet metal laser cutting services offer unparalleled detail and precision for the most intricate designs.

- Utilize our advanced laser technology for flexibility in cutting various shapes and sizes without the need for tool changes.

- Experience the precision of +/-0.1 mm, allowing for high accuracy and eliminating the need for additional tolerances.

Laser Cutting Efficiency & Speed

- Benefit from the rapid processing capability of our laser cutters, ensuring swift turnaround for your projects.

- The high-speed laser cutting minimizes material waste and delivers the exact cuts required for custom parts.

Robust Metal Punching Capabilities

Versatile Punching Services

- In addition to laser cutting, we maintain the traditional capabilities of standard punch machines.

- Our punching services are optimized for parts that are dense with holes and require tapping, offering a lower operating cost.

State-of-the-Art Laser Cutting & Punching Equipment

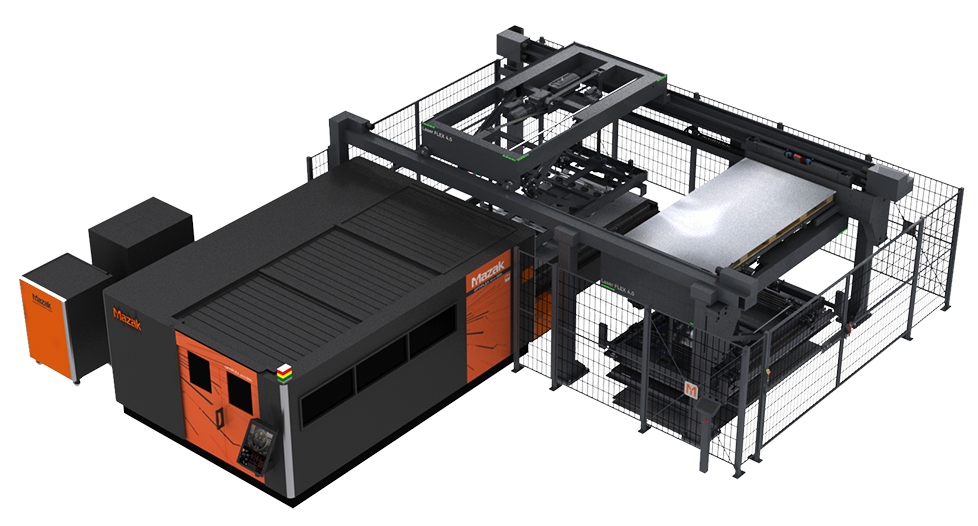

Mazak Optiplex 3015 DDL

- Jensen Metal Products utilizes the Mazak Optiplex 3015 DDL, a 4000 watt fiber optic laser capable of incredibly fast processing speeds up to 2,000+ inches per minute.

- This advanced technology allows for cutting up to 3/4″ thick mild steel, 5/8″ stainless steel, and ½″ aluminum with high precision.

- The Mazak Optiplex 3015 DDL is equipped with 17 material stations that enable automated loading and unloading while cutting, which facilitates “lights out” operation for 24/7 production.

Mazak MkIII RTC

- The Mazak MkIII RTC, another state-of-the-art laser, incorporates a 4 axis with tapping and rotary tube chuck (RTC), perfect for processing various metal thicknesses and adding intricate holes or cutouts.

- With its integrated tapping head and RTC, Jensen Metal Products can handle complex tasks like adding holes or cutouts to all sides of any tube and cutting it to length in a single operation.

LVD Axel 3015 L Shuttle Table Laser

- High-Power Laser: With a 4000 watt laser capability, it can handle a variety of materials and thicknesses, cutting up to ¾″ mild steel, ½″ stainless steel, and 3/8″ aluminum.

- Automation: It includes load/unload automation, which enhances productivity by allowing for continuous operation and reducing manual handling.

- It is equipped with a GE FANUC Series 160i-L Control unit, which ensures precise control over the laser cutting process.

Strippit 1250 Laser Turret Punch

- With a 33-station turret that includes auto-index stations, Jensen Metal Products can perform a wide variety of punches and shapes.

- Punching accuracy of ± 0.1 mm and repetitive accuracy of ± 0.05 mm allow for consistent and precise metal fabrication.

- The machine’s 200 kN punching force across different models (P-1212, P-1225, P-1525) ensures it can handle various material thicknesses with ease, up to 6.35 mm.

At Jensen Metal Products, we are committed to providing our customers with the highest level of service and quality. Contact us today to learn how our laser cutting and punching services can support your next project with precision and efficiency.