Quality Control

We are committed to ensuring top quality on all of our products. We conduct a 100% first and last piece inspection on all orders. Additionally, we perform periodic inspections at every step of fabrication in accordance with ISO 9001:2015 requirements. Our quality technicians are trained to operate a wide range of quality control equipment including tape measures, calipers, micrometers, a Virtek LaserQC part scanner and CMMs (coordinate measuring machines). All inspection equipment is third-party calibrated to ensure accurate results.

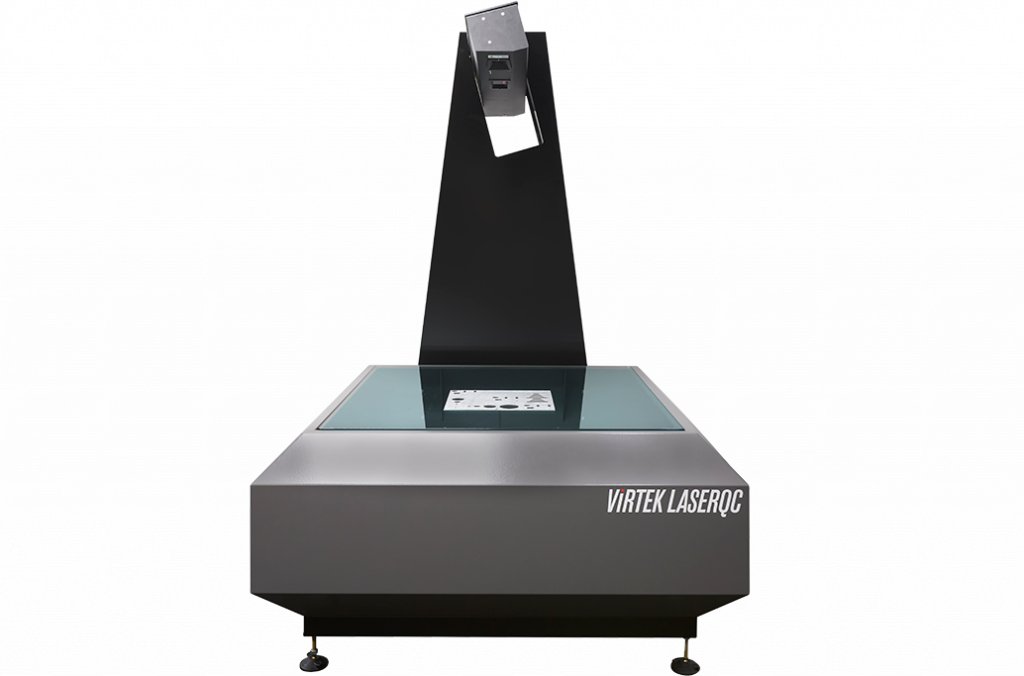

Virtek LaserQC

- Measures accuracy of 2D parts to a tolerance within 0.002″

- Verifies system calibration before each scan

- Captures more than 500 data points per second

Inspection Documentation

Upon job completion, our quality technicians can provide documented inspection paperwork from ISIR (initial sample inspection report) to Level 3 PPAP (production part approval process), as well as PFMEA, SPC controls or a CoC (certificate of conformance).*

* Note that quality paperwork must be requested at the time of order and may carry an additional cost depending on the complexity of the requirements.